amaani POLYFLAKES

Driving Sustainable

Plastic

Recycling Solutions

Leading the Industry with Expertise and Innovation in PET & PP Recycling

about us

"Be part of the solution,

not The pollution"

Amaani Polyflakes is driven by a passion for sustainability and a commitment to excellence. With years of experience in the recycling industry, we have honed our expertise to become pioneers in the field of plastic Recycling management. Our state-of-the-art facilities and cutting-edge technology enable us to recycle plastic materials efficiently and responsibly, minimizing environmental impact while maximizing resource efficiency.

Industries

Industries we serve

Amaani Polyflakes

Quality promise

At Amaani Polyflakes, quality is our top priority. We adhere to stringent quality control measures throughout the recycling process, ensuring that our product flakes meet the highest standards of quality performance, and reliability. Our dedicated quality assurance team conducts rigorous inspections to guarantee consistency and excellence in every batch of poly flakes we produce.

AMAANI POLYFLAKES providing reliable products, systems, services and solutions and to continual improvement in Quality Management System to achieve enhanced customer satisfaction by:

- Developing and applying new technology

- Work closely with Customers and External Providers

- Understanding and meet the Needs & Expectations of Interested Parties

- Ensuring Engagement of all employees and promoting Risk based Thinking

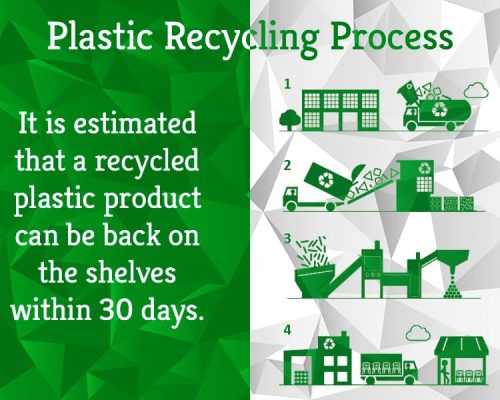

process

Recycling process

Collection

We collect discarded plastic materials from various sources,

including households, industries, and recycling centers.

Segrigation & Belling

In the world of electronics, Segrigation is a crucial process that ensures the quality of components, while Belling is a technique used to join metal parts together with precision and strength.

Sorting & Cleaning

The collected plastic materials are sorted based on their

type and quality to ensure uniformity in the recycling process.

The sorted plastic materials undergo thorough cleaning to

remove any contaminants, such as dirt, debris, and labels.

Shredding

The cleaned plastic materials are then shredded into small

pieces or flakes using specialized equipment.

Washing

The shredded plastic flakes undergo multiple washing

stages to further remove impurities and residues

Drying

The washed plastic flakes are dried to eliminate moisture

and prepare them for further processing

Quality Control

The final polyflakes undergo stringent quality control checks

to ensure they meet our standards of excellence before

being packaged and delivered toourcustomers.

Packing

The dried plastic flakes are melted and extruded to form

pellets or granules, which can be used to manufacture

new products.

Mission and vision

Our mission is to revolutionize the recycling industry by providing sustainable solutions that protect the planet and promote a circular economy. We envision a future where plastic waste is no longer a threat to the environment but a valuable resource that can be continuously reused and recycled. Through innovation, collaboration, and a relentless pursuit of excellence, we aim to make this vision a reality.

In future our company planning to be a authorized waste management firm in survival cities .

Wanna Talk To Us?

wonderful serenity has taken possession of my entire soul, like these sweet

Responsibility

Our responsibility

Occupational Health and Safety Policy

We believe that the occupational health and safety (OH&S) of our employees and interested parties is the most important element of our success as a company and that

all employees along with our interested parties are equal partners in identifying and

reducing risks.

We are committed to operating our business as per our relevant context in a safe, healthy and professional manner such that these values become integral to our everyday culture.

We will strive for continual improvement in implementation of the OH & S management system by:

- Developing and applying new technology

- Work closely with Customers and External Providers

- Understanding and meet the Needs & Expectations of Interested Parties

- Ensuring Engagement of all employees and promoting Risk based Thinking

- Identifying and implementing OH&S opportunities.

- Consultation and participation with workers and other relevant interested Parties to implement and improve OH&S.

- Reducing risk of damage to property and environment

- Improving work environment

- Creating meaning ways for employees and interested parties engagement in OH & S programs.

This policy shall apply to all employees and all people at or facilities including employees, vendors and their employees and visitors.